DTF Gang Sheet Tutorial

Create your custom gang sheets with thousands of our DTF designs or use your own designs! Click below to learn how!

DTFs (Direct To Film) transfers are revolutionizing the clothing decorating world due to their incredible ease of use, versatility, and durability. If you are just beginning your journey of looking into DTFs and what they have to offer, let me assure you that you are on the right path!

In this article our purpose is to quickly cover a variety of topics related to DTFs without going into great details but we will also link to more in depth articles for each section.

Now, lets jump into it!

It is well known that traditional screen printing produces a high quality print for single color designs, especially with a high order volume, but if the design integrates more colors, it is left unable to match the full color designs of DTFs.

Not only that but screen printing small orders is unfeasible due to the intensive time required to create the screens, which is why so many screen printers have minimum order requirements of 25+ and extra charges for more colors.

DTFs on the other hand do not have any limitations regarding colors as they are full color and can replicate any image with incredible accuracy. They are also very flexible as the images are handled digitally and burning screens is no longer necessary.

Screen printed designs are legendary for long lasting, often times lasting longer than the shirt itself! From our own experiments we are seeing that our Armor Ink DTF are holding up on par with the best of screen prints! Testing is still underway and our prints have already been washed 70+ times, so we absolutely can't wait to reveal our longevity in a future article showcasing them.

DTG (Direct To Garmet) was a technology that was heralded by many to replace screen printing. Although it is a fantastic technology it is rapidly becoming replaced by DTF technology.

DTG requires the clothing decorator to apply a pretreatment chemical to allow the ink to adhere properly to the shirt. This process, if not done correctly, causes inks to peel, have incorrect coloring, and fade much faster than intended. However, direct to film avoids this messy and problematic process by skipping the pretreatment chemical by using a special "glue" powder that is baked into the ink on the film as it is produced.

DTF also has a higher wash cycle lifespan (very similar to screen printed) that DTG simply can't compete with.

Vinyl has been used in the apparel decorating industry for many years and it is often times the entry point for small business owners as they enter this industry. Vinyl can produce a great product when properly applied but this is often a struggle for many business owners. We have personally seen far to many Vinyl products begin to peel after just a few washes which is a disservice to your customers and never a good look for your business.

Vinyl also is well known for the intensive amount of work and long amounts of time to "weed" the vinyl. This time spent can greatly affect your bottom line when you consider your profits from an hourly view point.

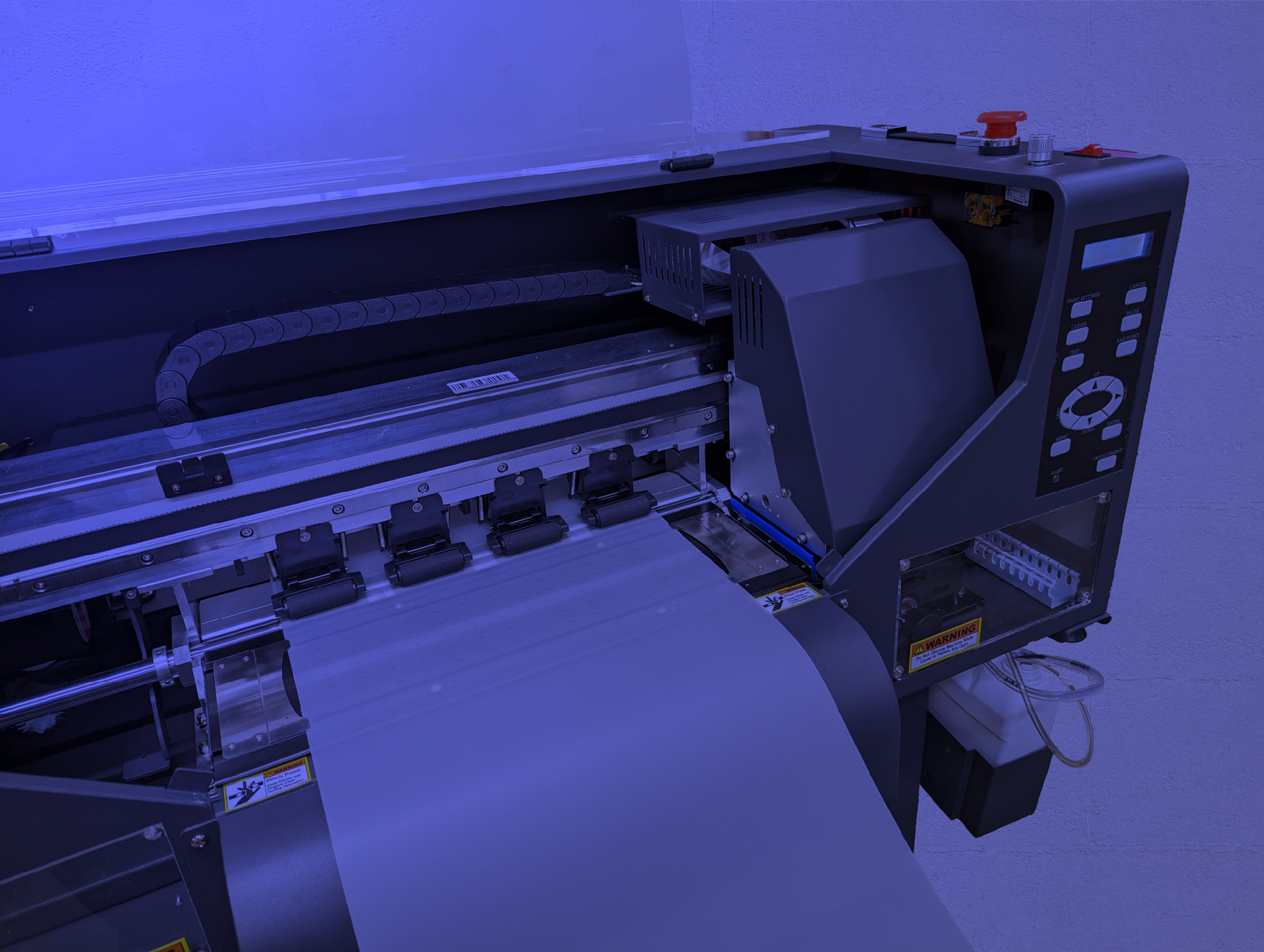

Armor Ink DTFs do not have any of the short comings of Vinyl. Our transfers are produced and cured properly with our industrial equipment, using a top quality ink/glue blend. We know that, when you use a heat press as we specify, you will never see a transfer peeling from the shirt.

On top of that our transfers require absolutely no time spent weeding or preparing the transfer. They ship 100% ready for you to apply to your garments!

Now that we have quickly compared DTFs to their competition here are some quick facts about DTFs.

Some common uses for DTFs are:

Shop our Ready To Press Transfers:

https://armorink.com/collections/all

-or-

Upload/Build your Custom Gang Sheets:

https://armorink.com/collections/create-your-gang-sheets-here

Create your custom gang sheets with thousands of our DTF designs or use your own designs! Click below to learn how!

Not quite ready to use the gang sheet builder? Just select the size you want printed, upload your file, and receive your perfectly made DTF transfer!